Info@brilliant-optoelectronics.com

+86(0)576 -84521666

Welcome To Zhejiang Brilliant Optoelectronic Technology Co.,Ltd.

Advanced equipment

Sublimator

Purpose: The sublimator is used for the purification and separation of small molecular organic materials. The main processing objects are organic materials with sublimation, or mixtures with mobile phase characteristics, such as organic acousto-optic products (such as organic photoelectric materials for organic light-emitting display) or nano materials. Main components: The sublimator consists of heating system and vacuum system. The heating system includes PID regulator, electric heating wire, temperature sensing probe and so on. The vacuum system includes sublimation chamber, vacuum sensor, molecular pump, mechanical pump and so on. Automatic operation can be realized through PLC connection. Principle of purification: In high vacuum, the materials in Shenghua boat are heated to produce steam. The molecular properties of impurities in the vapor are different from those of the product, and the deposition temperature is different. Adjust the temperature of sublimation collection tube after Shenghua boat to deposit the product and impurities in different sublimation tubes, so as to achieve the purpose of product separation and purification.

Sublimator

Purpose: The sublimator is used for the purification and separation of small molecular organic materials. The main processing objects are organic materials with sublimation, or mixtures with mobile phase characteristics, such as organic acousto-optic products (such as organic photoelectric materials for organic light-emitting display) or nano materials. Main components: The sublimator consists of heating system and vacuum system. The heating system includes PID regulator, electric heating wire, temperature sensing probe and so on. The vacuum system includes sublimation chamber, vacuum sensor, molecular pump, mechanical pump and so on. Automatic operation can be realized through PLC connection. Principle of purification: In high vacuum, the materials in Shenghua boat are heated to produce steam. The molecular properties of impurities in the vapor are different from those of the product, and the deposition temperature is different. Adjust the temperature of sublimation collection tube after Shenghua boat to deposit the product and impurities in different sublimation tubes, so as to achieve the purpose of product separation and purification.

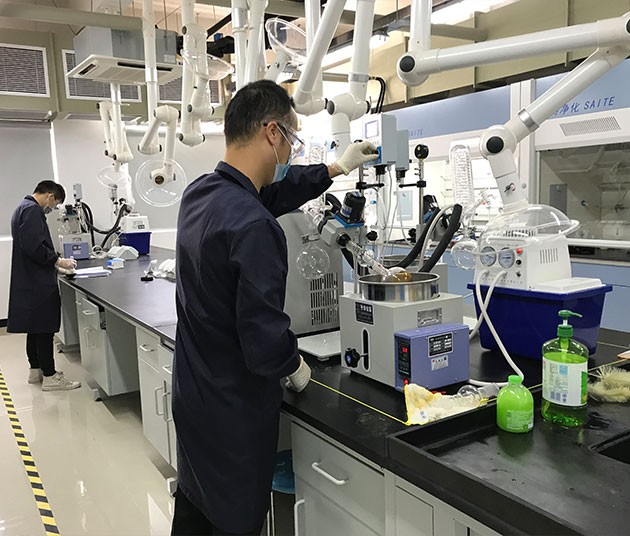

Complete production, testing and R & D platform

Ø 2000m2 is used for material production with a monthly synthetic capacity of more than 2 tons;

Complete production, testing and R & D platform

Ø 2000m2 is used for material production with a monthly synthetic capacity of more than 2 tons;

Ø Full set of analytical and testing equipment: PL, UV, TGA, DSC, LC-MS, UPLC, GC-MS, and CV;

Ø The 1200 M2 1000 grade clean room can accommodate 20 sets of sublimation devices. At present, 5 × φ 300 small molecule sublimator has a purification capacity of 500kg per month;

Ø All production processes conform to ISO process standards;

Ø Research and development laboratory, each laboratory has 8 lampblack hoods, which can accommodate more than 50 synthetic engineers at the same time;

Complete production, testing and R & D platform

Ø 2000m2 is used for material production with a monthly synthetic capacity of more than 2 tons;

Complete production, testing and R & D platform

Ø 2000m2 is used for material production with a monthly synthetic capacity of more than 2 tons;

Ø Full set of analytical and testing equipment: PL, UV, TGA, DSC, LC-MS, UPLC, GC-MS, and CV;

Ø The 1200 M2 1000 grade clean room can accommodate 20 sets of sublimation devices. At present, 5 × φ 300 small molecule sublimator has a purification capacity of 500kg per month;

Ø All production processes conform to ISO process standards;

Ø Research and development laboratory, each laboratory has 8 lampblack hoods, which can accommodate more than 50 synthetic engineers at the same time;

Quality management

ISO 9001:2015 QC 08000:2017

ISO 45001:2018 ISO 14001:2015

Scientific research cooperation

-

Nankai University

Scientific research cooperation

-

Fudan University

Scientific research cooperation

-

South China Normal University

Scientific research cooperation

© Copyright 2020 - 2030. Zhejiang Brilliant Optoelectronic Technology Co.Ltd. All Rights Reserved.

浙ICP备2020032054号 Technical support:

Yingzi.tech